Bidiyo

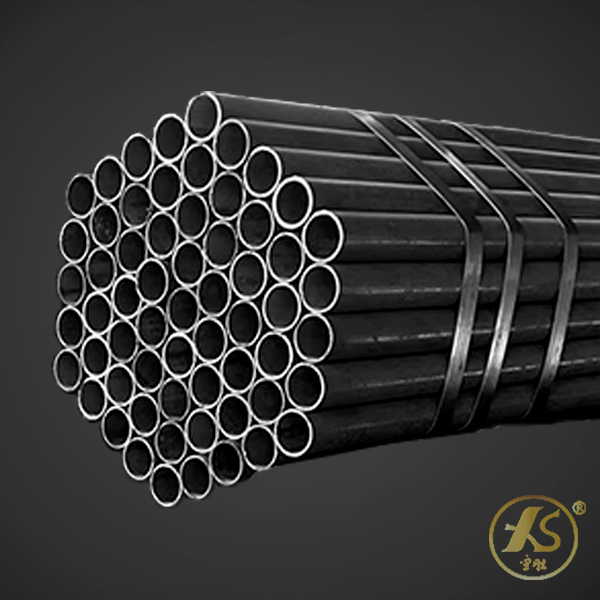

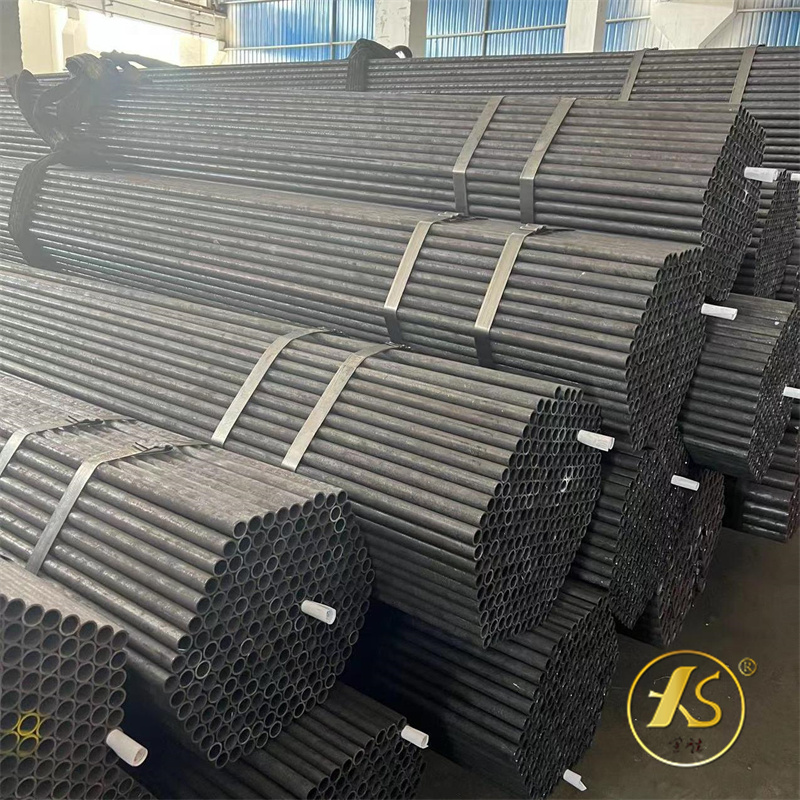

Bututun ƙarfe mara ƙarfi don matsi

| Kayan samfur | St37.0/St44.0/St52.0 |

| Ƙayyadaddun samfur | |

| Daidaitaccen samfurin da aka yi amfani da shi | DIN 1629 |

| Matsayin bayarwa | |

| Kunshin kayan da aka gama | Karfe bel kunshin hexagonal / Fim ɗin filastik / jakar saƙa / fakitin majajjawa |

Tsarin Samfuran Samfura

Tube babu komai

Dubawa (ganowa na gani, duban ƙasa, dubawar girma, da gwajin macro)

Yin sarewa

Perforation

Thermal dubawa

Pickling

Nika dubawa

Pickling

Lubrication

Zane mai sanyi (ƙarin hanyoyin hawan keke kamar magani mai zafi, pickling da zanen sanyi yakamata su kasance ƙarƙashin takamaiman ƙayyadaddun bayanai)

Annealing (NBK)

Gwajin aiki (kayan injina, kadarar tasiri, lallausan ƙasa, walƙiya, da taurin)

Mik'ewa

Yanke Tube

Gwajin mara lalacewa (eddy current, da ultrasonic)

Binciken samfur

Nitsar da mai mai hana lalata

Marufi

Wajen ajiya

Kayan Aikin Samfura

Na'ura mai sausaya / injin sarewa, murhun katako mai tafiya, injin huɗa, injin ɗigon sanyi mai tsayi, tanderu mai zafi, da injin daidaitawa

Kayan Gwajin Samfura

A waje micrometer, bututu micrometer, bugun kira gage, vernier caliper, sinadaran abun da ke ganowa, spectral ganowa, tensile gwajin inji, Rockwell hardness tester, tasirin gwajin inji, eddy halin yanzu flaw gane, ultrasonic flaw detector, da hydrostatic gwajin inji

Aikace-aikacen samfur

Kayan aikin sinadarai, jiragen ruwa, bututun mai, sassan mota, da aikace-aikacen ƙira na inji

Me yasa zabar mu

Muna mai da hankali kan ci gaba da haɓaka ingancin ayyukanmu. Tare da saka hannun jari na baya-bayan nan a cikin tsaka-tsakin layin gamawa, aiwatar da kawar da fashewar ruwa, da ci gaba da shigar da kayan aikin thermal, muna ba da inganci, mafita na musamman. Hanyarmu ta masana'antu tana haɗawa da narkewa, mirgina, hudawa da ƙare ayyukanmu, yana taimakawa wajen tabbatar da kula da inganci daga farko zuwa ƙarshe. Hanyoyin bututun injin ɗin mu marasa sumul sun haɗa da huda (rotary forging), maganin zafi, da gwaji da ƙarewa.

Kunshin na carbon karfe bututu maras kyau

Filayen filastik da aka toshe a bangarorin biyu na ƙarshen bututu

Ya kamata a nisance shi ta hanyar ƙulla madaurin ƙarfe da lalacewar sufuri

Ya kamata sians ɗin da aka haɗa su zama iri ɗaya kuma su kasance masu daidaituwa

Ya kamata a fito da nau'in bututun ƙarfe ɗaya daga tanderu iri ɗaya

The karfe bututu yana da wannan tanderu lambar, guda karfe gradethe guda takamaiman