Bidiyo

Bututun ƙarfe mara ƙarfi da bututu don tukunyar jirgi mai ƙarfi

Tsarin Samfuran Samfura

Tube babu komai

Dubawa (ganowa na gani, duban sararin sama, da duban girma)

Yin sarewa

Perforation

Binciken thermal (karfe na gawa yana buƙatar maganin zafi)

Pickling

Nika dubawa

Lubrication

Zane mai sanyi

Lubrication

Zane-zanen sanyi (ƙarin hanyoyin hawan keke kamar maganin zafi, pickling da zanen sanyi yakamata su kasance ƙarƙashin takamaiman ƙayyadaddun bayanai)

Daidaita / daidaitawa + zafin jiki

Gwajin aiki (kayan injina, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa, taurin kai, lallausan ƙasa, da walƙiya)

Mik'ewa

Yanke Tube

Gwajin mara lalacewa (eddy current, da ultrasonic)

Gwajin Hydrostatic

Binciken samfur

Marufi

Wajen ajiya

Kayan Aikin Samfura

Na'ura mai sausaya, na'ura mai zato, murhun katako mai tafiya, injin huɗa, injin ɗigon sanyi mai tsayi, tanderu mai zafi, da injin daidaitawa.

Kayan Gwajin Samfura

Aikace-aikacen samfur

Amfani

Daidaitaccen bututun ƙarfe a cikin gadon fa'idodin bututun ƙarfe mara nauyi a lokaci guda, amma kuma yana da wasu halaye na kansa. Tare da madaidaicin sassa na zobe na masana'anta, na iya haɓaka amfani da kayan aiki, sauƙaƙe tsarin masana'anta, adana kayan aiki da sa'o'in sarrafawa, kamar zoben mirgina, saiti jack, da sauransu, an yi amfani da su sosai don kera madaidaicin bututun ƙarfe. Gabatar da aikace-aikace na madaidaicin bututu don adana ƙarfe, inganta ingantaccen aiki, rage tsarin sarrafawa ko zuba jarurruka na kayan aiki yana da muhimmiyar mahimmanci, zai iya adana farashin da sa'o'i masu aiki, inganta samarwa da amfani da kayan aiki, yayin da yake taimakawa wajen inganta ingancin samfurin, rage farashin, don inganta ingantaccen tattalin arziki yana da muhimmiyar mahimmanci. Gabaɗaya, masana'antun da ke buƙatar daidaitattun bututu suna amfani da bututun da ba su da kyau, kuma waɗanda ba su buƙatar daidaito galibi suna amfani da bututun da ba su da kyau, bayan haka, farashin madaidaicin bututu masu ƙayyadaddun ƙayyadaddun ƙayyadaddun bututun ya fi na bututun mara kyau.

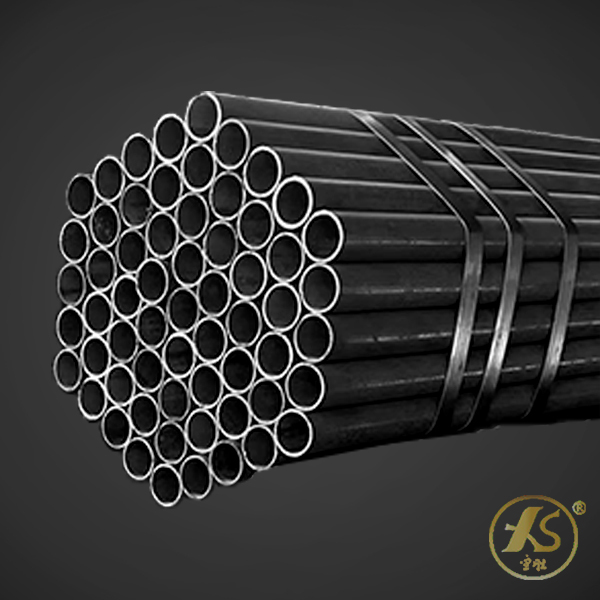

Kunshin na carbon karfe bututu maras kyau

Filayen filastik da aka toshe a bangarorin biyu na ƙarshen bututu

Ya kamata a nisance shi ta hanyar ƙulla madaurin ƙarfe da lalacewar sufuri

Ya kamata sians ɗin da aka haɗa su zama iri ɗaya kuma su kasance masu daidaituwa

Ya kamata a fito da nau'in bututun ƙarfe ɗaya daga tanderu iri ɗaya

The karfe bututu yana da wannan tanderu lambar, guda karfe gradethe guda takamaiman